I made progress on the rear turn signals. My hands are numb from all the grinding. Thank you spell check 'cause I'm making a mess typing with numb fingers.

These will keep the nut theme I have going back there. Once done the will be welded to the end of the frame.

Custom motorcycle build, We take you along as we turn a stock 1980 CX500 into a cafe racer. I'm now messing with a Goldwing

Wednesday 26 December 2012

Sunday 23 December 2012

More seat shenanigans

The center stand is a mess. I'll sand blast it and make it nice. Off it comes

My rear signal LED's are in. They are truck clearance lamps. I intend to put them in some big nuts I found at work. They will match the tail lamp perfectly.

That blue thing is supposed to make my LED's flash OK, I have no efing clue where or how to use it but apparently I need it. I think Mr Double J will know.

I think I have to do something with the seat before I go anywhere else. The seat will show me how much room I have underneath for the electronics box and if I can get the battery to fit up there.

I really want to use the stock latching system somehow.

I think I cut away as much of the seat pan as I dare, it's about the size I want. I'll hold the cover on with rivets so I have to make holes.

Now for the latching system. The captive nuts used for the latches will be used to hold my fender...

so I need 2 more captive nuts under there. Down in the basement goes the frame. I pop it on the bench and weld on a couple of nuts and spring posts.

A quick shot of primer and the latches go on.

Not bad, now I only have to make the pieces that the latches grab onto and I'm laughing.

My rear signal LED's are in. They are truck clearance lamps. I intend to put them in some big nuts I found at work. They will match the tail lamp perfectly.

That blue thing is supposed to make my LED's flash OK, I have no efing clue where or how to use it but apparently I need it. I think Mr Double J will know.

I think I have to do something with the seat before I go anywhere else. The seat will show me how much room I have underneath for the electronics box and if I can get the battery to fit up there.

I really want to use the stock latching system somehow.

I think I cut away as much of the seat pan as I dare, it's about the size I want. I'll hold the cover on with rivets so I have to make holes.

Now for the latching system. The captive nuts used for the latches will be used to hold my fender...

so I need 2 more captive nuts under there. Down in the basement goes the frame. I pop it on the bench and weld on a couple of nuts and spring posts.

A quick shot of primer and the latches go on.

Not bad, now I only have to make the pieces that the latches grab onto and I'm laughing.

Sunday 16 December 2012

I finally almost, just about finished the plate bracket. It's now reinforced with some cross members and I've put on some nuts to hold the copper or steel tubes that will hold the wiring for the tag lights.

And here's what it looks like on the bike.

It's primed and ready for paint, don't know what colour.

I removed the wheel and final drive again and gave the frame and diff a good cleaning. I was hoping the frame was not going to need paint but with all the little nicks and stuff on it I'm going to have to give it a coat of something.

Note that the center stand is down, not on purpose. The darn thing folded on me and almost got my fingers.

Anyhow, this is as naket as it gets.

Maybe not, I should do something about that nasty looking stand.

And here's what it looks like on the bike.

It's primed and ready for paint, don't know what colour.

I removed the wheel and final drive again and gave the frame and diff a good cleaning. I was hoping the frame was not going to need paint but with all the little nicks and stuff on it I'm going to have to give it a coat of something.

Note that the center stand is down, not on purpose. The darn thing folded on me and almost got my fingers.

Anyhow, this is as naket as it gets.

Maybe not, I should do something about that nasty looking stand.

Sunday 9 December 2012

License plate bracket

You probably had no idea what I kept talking about with this license plate bracket. In the words of one of my highly respected colleges KABLAMO!!

Well here it is, not quite finished but along enough for you to get the idea.

Shorten it, clean it, paint it run some wires for tag lights and put a bracket on. KABLAMO!!

Well here it is, not quite finished but along enough for you to get the idea.

Shorten it, clean it, paint it run some wires for tag lights and put a bracket on. KABLAMO!!

More parts come off

Mr. G came over today to help. We striped off more parts off of the frame. The rear brake linkage came off after taking a reference photo, who knows if I'll remember hoe it goes in.

Before we took off the front end we discussed some possibilities for the handle bars. I don't want clubmans, I think they'll make the bike to uncomfortable so I'll use the shorter ones off of the Custom.

These are a few positions.

Time to remove the wheel and shocks. I read somewhere that If you crack the top shock nut while it's still in the triple tree this will make taking them apart later easier. So with that done Mr. G and I slide them out. Easy with two people, I probably would have been cursing if I tried that on my own.

We found the the head set had what Mr. G called memory steering, in other words when you move it back and forth you can feel some ratcheting feeling. We might as well open it up and see wht's up with that.

The races look fine but I might as well replace the whole thing, something is not good.

Now for the plate bracket. I welded another washer to a flat bar and tacked it all in place. The lines indicate where some bending will happen.

Now I just have to add reenforcing trellis and some bends.

Before we took off the front end we discussed some possibilities for the handle bars. I don't want clubmans, I think they'll make the bike to uncomfortable so I'll use the shorter ones off of the Custom.

These are a few positions.

Time to remove the wheel and shocks. I read somewhere that If you crack the top shock nut while it's still in the triple tree this will make taking them apart later easier. So with that done Mr. G and I slide them out. Easy with two people, I probably would have been cursing if I tried that on my own.

We found the the head set had what Mr. G called memory steering, in other words when you move it back and forth you can feel some ratcheting feeling. We might as well open it up and see wht's up with that.

The races look fine but I might as well replace the whole thing, something is not good.

Now for the plate bracket. I welded another washer to a flat bar and tacked it all in place. The lines indicate where some bending will happen.

Now I just have to add reenforcing trellis and some bends.

Sunday 2 December 2012

Cleaning and license bracket

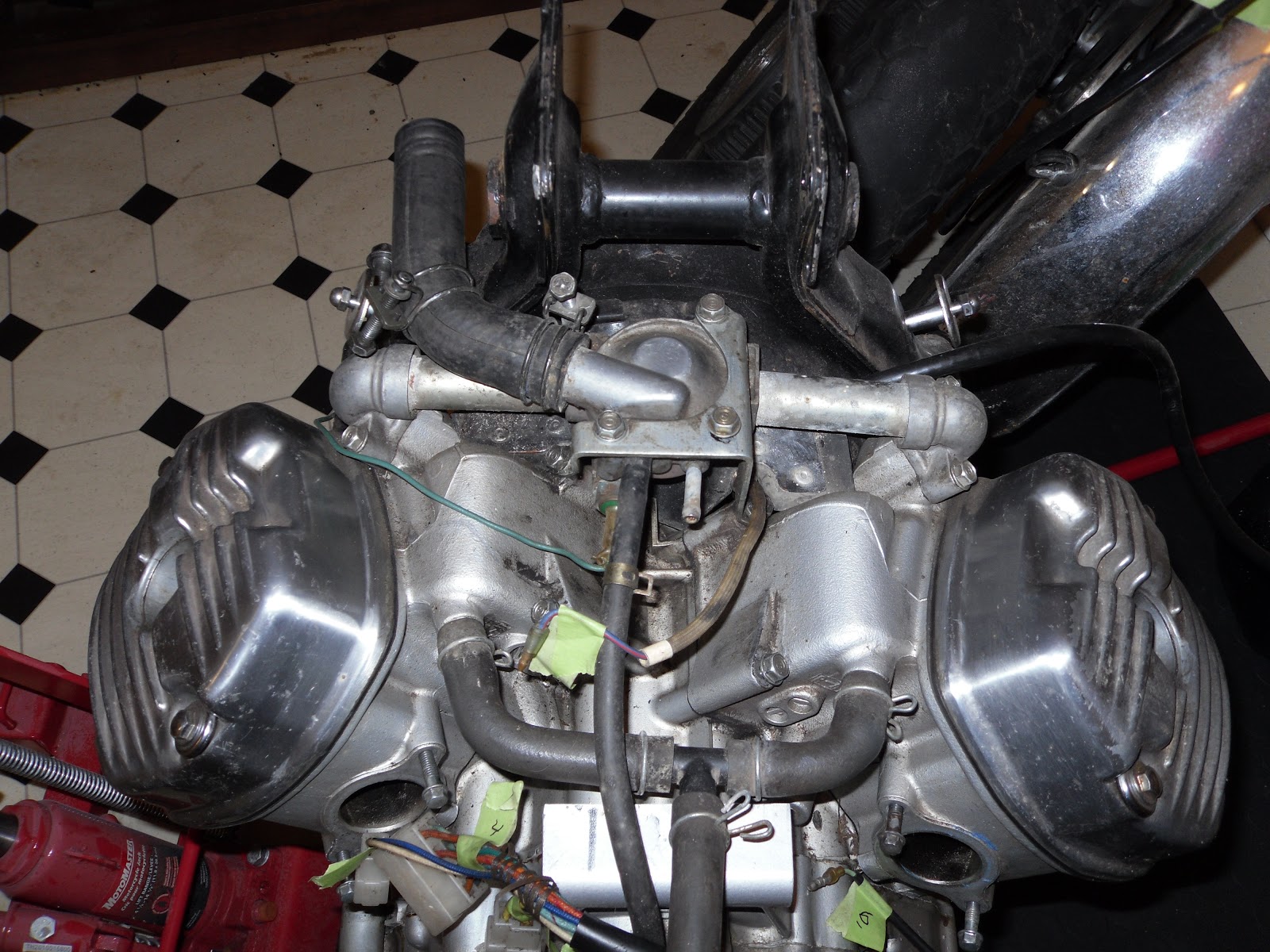

I might as well get to the engine. I don't have much to do on it really. I just have to get it looking good. it's a little grimy so it needs some cleaning.

I took the stator cover off, it had quite a bit of corrosion so I'll give it a sanding and refinish it.

Next I removed some of the piping and water pump cover, Mr. Double J is probably cringing at this but I promise this is as far as I go, OK maybe the valve covers but no farther.

Yummy, now I gave a craving for lime Jello. The stuff is in all the small passages so I'll have to figure out how to clean those.

This is what I took off, not much really, just enough to get at the dirt.

Now lets clean this sucker up. This is the before.

Add a little of pre-tune and let it sit a little. Once the pre-tune has time to work it's just a mater of wiping the grime off. It comes easily, that's a pretty engine. Wipe and wipe, I love this engine, it's so cool, hey I wonder where my Pink Floyd CDs are, that would be so dope right now, what was I doing...

Remember that when using harsh chemicals to ventilate the room well. A little time outside in the freezing rain and fresh air sets me right again. I open windows at both end fo the house to get a nice breeze going.

I used needle nose pliers with a shop towel on the end to get at the nooks and with a little time I'm left with a nice clean engine.

Now for the plate bracket. After last times fiasco I just wanted to deal with one of the mounting points at one time. I have some flat bat that I hope will give me some sort of a solid backbone for the bracket. I cut a notch in it so that it takes the washer that will fit on the axle snugly.

Next I weld that sucker in.

Jeez, that's not bad. It actually looks like a weld and not like bubble gum. I'll clean that up a little later.

Here's a look at where it will sit, the idea is to have the plate floating behind the rear wheel.

I took the stator cover off, it had quite a bit of corrosion so I'll give it a sanding and refinish it.

Next I removed some of the piping and water pump cover, Mr. Double J is probably cringing at this but I promise this is as far as I go, OK maybe the valve covers but no farther.

Yummy, now I gave a craving for lime Jello. The stuff is in all the small passages so I'll have to figure out how to clean those.

This is what I took off, not much really, just enough to get at the dirt.

Now lets clean this sucker up. This is the before.

Add a little of pre-tune and let it sit a little. Once the pre-tune has time to work it's just a mater of wiping the grime off. It comes easily, that's a pretty engine. Wipe and wipe, I love this engine, it's so cool, hey I wonder where my Pink Floyd CDs are, that would be so dope right now, what was I doing...

Remember that when using harsh chemicals to ventilate the room well. A little time outside in the freezing rain and fresh air sets me right again. I open windows at both end fo the house to get a nice breeze going.

I used needle nose pliers with a shop towel on the end to get at the nooks and with a little time I'm left with a nice clean engine.

Now for the plate bracket. After last times fiasco I just wanted to deal with one of the mounting points at one time. I have some flat bat that I hope will give me some sort of a solid backbone for the bracket. I cut a notch in it so that it takes the washer that will fit on the axle snugly.

Next I weld that sucker in.

Jeez, that's not bad. It actually looks like a weld and not like bubble gum. I'll clean that up a little later.

Here's a look at where it will sit, the idea is to have the plate floating behind the rear wheel.

Sunday 18 November 2012

Fuddleduddle, that's Canadian speak for fk off.. See http://en.wikipedia.org/wiki/Fuddle_duddle

I tried to get the license plate bracket going today. I have all the metal I need, I have a welder but apparently I have no patience.

I have these cheap welding magnets and I used them to mock up the mounting like I wanted it.

Ok, so far so good. Plug in the welder and put the dog out to do his business, I don't have little doggy welding glasses.

Just a quick tack and we're good to go. As soon as I get even close to it with the welder it falls off the bike, damn. Rig it up again and this time I don't even make it to the welder, crap. Rig it up again and this time sparks fly. I let it cool then go to take it off. The thing falls apart, seems I put a glob of steel nowhere near where it should have been, mother f%##% ass licker D$%^k head. Try it again and this time it holds together, barely.

By this time Chico is at the back door looking in and I know what he's thinking, what the hell are you up to and whats with all the swearing.

Ok take it to the bench in the basement, lug the machine

Set up the magnets again and hook up the ground, turn on the machine and bring the business end near the thing. The ground pulls everything off the bench, BALLS C%$C %*@!^% &$*#@.

I use all four magnets and finally get the other piece on. Now we're getting somewhere.

Now keep in mind these rods are just a jig to hold the washers in the right configuration while I do the rest, they will be removed.

Take the thing to the bike for a test fit. How can this be, I"M HALF AN INCH OFF, it doesn't fit.

Fuddle Duddle

I tried to get the license plate bracket going today. I have all the metal I need, I have a welder but apparently I have no patience.

I have these cheap welding magnets and I used them to mock up the mounting like I wanted it.

Ok, so far so good. Plug in the welder and put the dog out to do his business, I don't have little doggy welding glasses.

Just a quick tack and we're good to go. As soon as I get even close to it with the welder it falls off the bike, damn. Rig it up again and this time I don't even make it to the welder, crap. Rig it up again and this time sparks fly. I let it cool then go to take it off. The thing falls apart, seems I put a glob of steel nowhere near where it should have been, mother f%##% ass licker D$%^k head. Try it again and this time it holds together, barely.

By this time Chico is at the back door looking in and I know what he's thinking, what the hell are you up to and whats with all the swearing.

Ok take it to the bench in the basement, lug the machine

Set up the magnets again and hook up the ground, turn on the machine and bring the business end near the thing. The ground pulls everything off the bench, BALLS C%$C %*@!^% &$*#@.

I use all four magnets and finally get the other piece on. Now we're getting somewhere.

Now keep in mind these rods are just a jig to hold the washers in the right configuration while I do the rest, they will be removed.

Take the thing to the bike for a test fit. How can this be, I"M HALF AN INCH OFF, it doesn't fit.

Fuddle Duddle

Subscribe to:

Posts (Atom)